The Low-Temperature Evaporative Light-Scattering Detector (LT-ELSD)

Basically all compounds which are less volatile than the mobile phase can be detected. Detection is based on a Universal property of all analytes and does not require the presence of any chromophoric group, electroactive group, etc.

The detector response is directly related to the mass of the eluted compound. Therefore it provides similar response factors for molecules with close structures and this is quite convenient to simplify quantification procedures or to make them possible when standards are not commercially available.

Gradient mobile phases can be used to analyze samples. Since the mobile phase is removed from the eluent before detection, a gradient can be performed to optimize the separation. With ELS detection, a broad range of mobile phase modifiers such as AcONH4, AcOH, HCOONH4, HCOOH, CO3NH4, TFA, HFBA, or N(C2H5)3 can be readily used to separate complex samples.

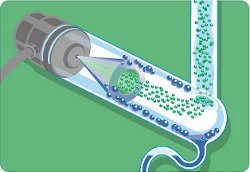

Step 1: Nebulization

Nebulization: The Eluent from the column is mixed with an inert gas and goes through the narrow orifice of a nebulizer to generate a homogeneous mist. This fine mist is composed of droplets of mobile phase containing the compound of interest.

SEDEX LT technology allows the selection of droplets as a function of their size in order to prevent larger droplets from entering the evaporation (drift) tube. Large droplets would require higher temperatures to be dried and are responsible for increased background noise.

Step 2: Evaporation

Evaporation of the Mobile Phase: The nebulized eluent goes through a heated drift tube to evaporate the mobile phase.

Solute molecules are obtained from the mist using a heated evaporation (drift) tube, at a low temperature. All SEDEX detectors are designed to evaporate mobile phases with high boiling points at very low temperatures. This unique feature minimizes the potential for evaporation or thermal decomposition of the compounds of interest, and makes the SEDEX LT technology a more reliable way to detect everything in the sample.

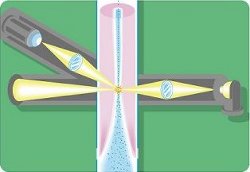

Step 3: Detection

Detection: The stream of solid particles enters a flow cell which includes a light source and a photomultiplier or a photodiode. The intensity of the light scattered by the particles is directly related to the mass of the eluted compound.

The solute molecules from the mist, assisted by Gas Supported Focusing (GSF), go through an optical head designed to measure the scattered light. GSF involves the addition of gas to focus the solute particles within the optical head for enhanced detection and safety.

All SEDERE detectors feature Low Temperature operation to ensure that the superb sensitivity is provided even for semi-volatile or thermally labile compounds. These detectors can be used with conventional analytical and preparative Liquid Chromatography, as well as with U-HPLC, HTLC, µ-HPLC, GPC, Flash Chromatography, CCC and SFC.

Low-Temperature detection

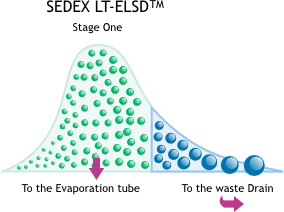

The unique design of SEDEX LT-ELSD Nebulization cell allows the selection of the droplets as a function of the size. Large droplets, which are more difficult to evaporate, are responsible for an increased noise level. In the glass nebulization cell, the largest droplets are simply discarded, so that the temperature can be lowered, without compromising the sensitivity (signal to noise ratio):

This diagram illustrates the selection of the droplets as a function of the size. The mist of droplets is created by the nebulizer, and is composed of droplets of various sizes. The nebulization cell acts as a real Size Exclusion Selector, so that the droplets of largest dimension (in blue on Figure) are evacuated to the waste. Only droplets which are below a size limit are allowed to flow through the drift tube.

Most of our competitors’ ELSDs do not select droplets and require higher temperatures to reach acceptable levels of noise during the analysis, resulting in much lower sensitivities for semi-volatile and thermo-labile compounds.

Selection of the droplets is a unique feature of SEDEX LT-ELSD and provides the real Low-Temperature evaporation, and the best sensitivity for all compounds.

Why Low-Temperature evaporation is important in ELS detection?

In an ELS detector, the nebulized eluent is evaporated by going through a heated tube. The temperature of this tube is undoubtedly the most critical parameter when optimizing detection. If the temperature is too high, semi-volatile or thermally labile compounds in the sample may evaporate or decompose and will not be detected.

SEDEX detectors can evaporate solvents with high boiling points at low temperatures. As an example, the SEDEX 90LT can completely evaporate a mobile phase composed of 100% H2O with a flow rate of 1mL/min at 32°C.

Also, our innovative design provides performance that is superior to that obtained from systems which require a special low temperature device!

Know more about our comparative study Frequently Asked Questions

SEDEX detectors can be used in different areas: conventional HPLC, U-HPLC, HTLC, µ-HPLC, GPC, Preparative HPLC, Flash Chromatography, Counter Current Chromatography and Supercritical Fluid Chromatography. Elsewhere, SEDEX detectors can be connected to any Chromatography system via A/D converters or directly using RS-232 or USB with our latest models.

To shift from an application to another (e.g. HPLC to U-HPLC) just replace the nebulizer of the detector by the correct one. Nebulizer replacement is very easy and can be done in less than 2 minutes.

Three important steps located in three different parts can be defined during the LT-ELSD process: Nebulization, Evaporation and Detection.

1. Nebulization

This first step transforms the whole liquid phase flowing from the LC column into fine droplets. The smaller the droplet size, the lower the temperature needed to evaporate the liquid phase. With SEDEX detectors, the nebulizer and the nebulization glass chamber are designed to eliminate the biggest droplets of the solvent.

2. Evaporation

This second step begins when the droplets are carried by the gas flow into the evaporation tube. SEDEX detector drift tubes have been designed to optimize the efficiency of the required evaporation with the lowest temperatures. The solvent is completely removed to produce particles of solutes. Practically, a temperature in the range 30°-60°C is sufficient to evaporate most of the solvents used in HPLC.

3. Detection

Analyte particles pass through a detection chamber where they are hit with an incident light beam. The amount of light scattered by the particles is measured using a photomultiplier tube or a photodiode and an electronic device. In SEDEX detectors a secondary gas inlet is used to concentrate the particles in the centre of the detection chamber to further increase sensitivity and to prevent this part from any contamination.

Since the mobile phase is evaporated before detection, any gradient system can be performed with absolutely no effect on the baseline when the solvents have got similar RAE levels.

A broad range of volatile additives can be used with LT-ELSD. Among these: acids (formic acid, acetic acid, trifluoroacetic acid…), bases (ammonia, triethylamine…), buffers (ammonium formate, ammonium acetate, ammonium carbonate…), ion-pair reagents (pentafluoropropionic acid, heptafluororobutyric acid…), these compounds can conveniently modify the mobile phase to separate complex samples.

Non-volatile additives (such as sodium or potassium phosphates or sulphates) are not compatible with LT-ELSD and should not be used. Indeed, they may contaminate and even drastically damage some parts of the detectors. However, these additives can be easily replaced by corresponding volatile ones.

Gas may come from laboratory lines or gas cylinders and typical consumption is less than 3L/min. The gas does not require a high purity but it should be free of oil and particles. The standard operating pressure is 3.5bar (51psi), except for SEDEX FP (2.0bar, 29 psi).

For better performances, SEDERE recommends using at least a gas regulator with filter (0.01µm) and manometer.

Moreover, to further improve between-day RSD%, an internal standard can also be included in the samples.

Most of evaporative light-scattering detectors have limited direct linearity, within one or sometimes two orders of magnitude, with correlation coefficients over 0.99. However, this could be quite satisfactory for the majority of QC analyses, particularly when the concentration range for quantitation is limited to 60% and 140% of the target value. When larger ranges of concentration are required evaporative light-scattering detection generally provides a sigmoid, logarithmic or quadratic response depending on the application, but most of the HPLC software allow the users to easily select the equation which will directly provide the best correlation with the detector response. Otherwise, the standard log-log transformation can be used.

Due to an innovative and efficient optical head design, our latest Model SEDEX 90LT drastically increased the overall direct linearity range with typical correlation coefficients over 0.995.

Make sure that the siphon of the nebulizer glass chamber is always filled and the liquid level is stable and equal at both sides.

Make sure that the drain and exhaust tubes are correctly installed and the extraction of the exhaust device is not too strong.

Elsewhere, other particular considerations should be brought to the mobile phase (low RAE), to the gas (clean and with a stable pressure), to the column quality (no phase “bleeding”) and to the HPLC equipment which should be in a good working condition.

For non-volatile compounds, select a high evaporation temperature (e.g. 50°-60°C) to completely evaporate the mobile phase, thus minimizing the baseline noise and obtain the highest sensitivities (highest S/N ratios).

Elsewhere, the outstanding and unrivalled advantage of the Low-Temperature Technology of SEDEX detectors enables the highest sensitivities for semi-volatile and thermo-labile compounds. Indeed, just setting the temperature in the range of 30°-40°C also provides the highest signals for these compounds without compromising the evaporation of the mobile phase.

Alternatively, SEDEX detectors can be connected in parallel with MS detector by means of a flow splitter.

In any case, check that all connections from the column are properly done to avoid any extra dispersion.